Grede Charts a New Course Focused on Engineering Partnerships and Technical Excellence

October 22, 2021

Originally published by Design2Print Magazine October 22, 2021

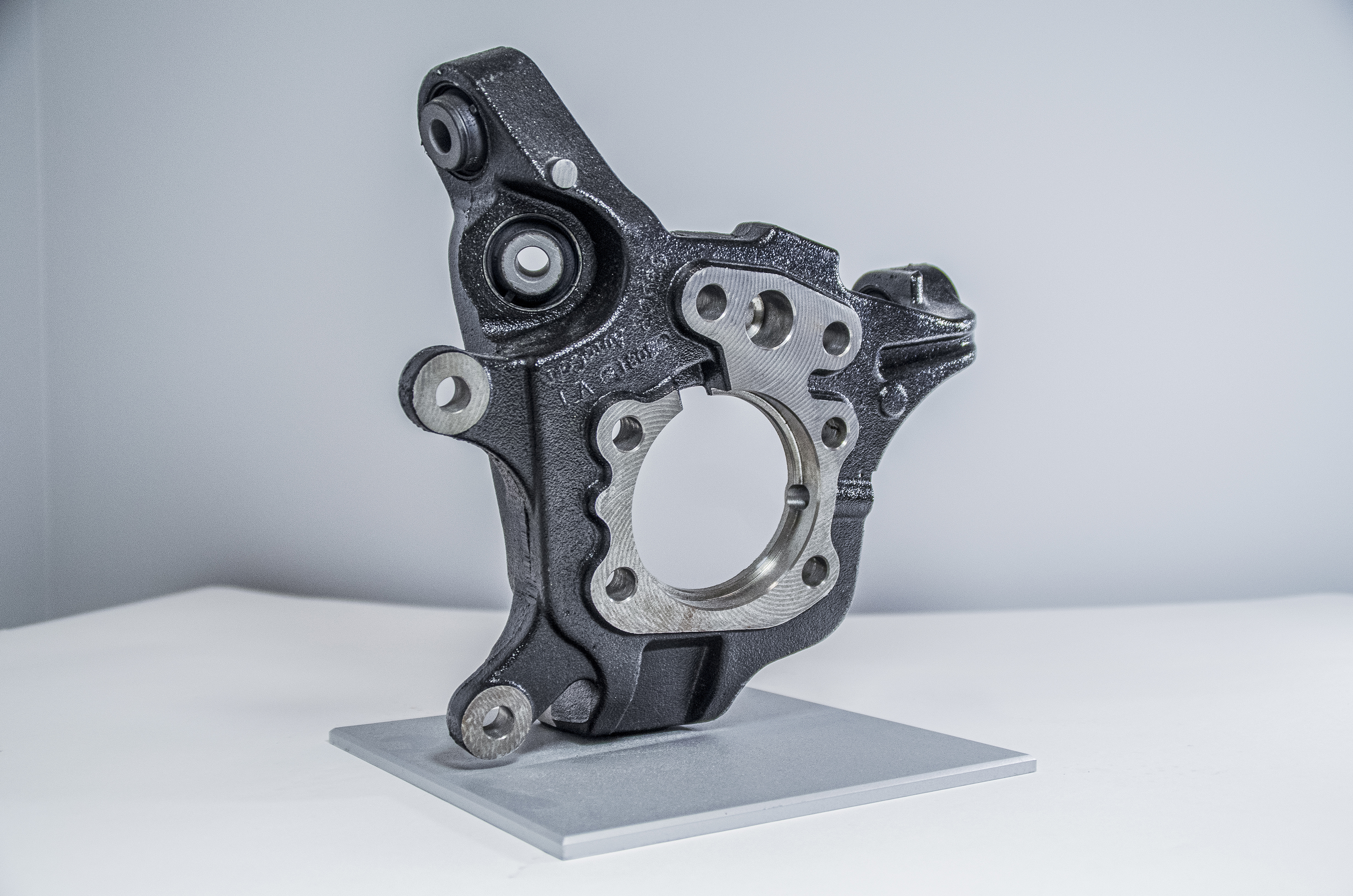

An automotive steering knuckle manufactured by Grede. (Photo courtesy of Grede Foundries, Inc.)

An automotive steering knuckle manufactured by Grede. (Photo courtesy of Grede Foundries, Inc.)

Amid ongoing supply challenges, a manufacturer of engineered ductile and gray iron castings is repositioning itself as a supplier of choice to the automotive, heavy truck, and industrial markets.

By Mark Shortt

Automakers have traditionally followed a predictable path to building a high-performing supply chain. It includes seeking out and carefully vetting the most capable suppliers, laying out stringent performance criteria, and rewarding those who meet them. But global supply chain disruptions resulting from COVID-19 and the semiconductor chip shortage have prompted an unsettling question: Is this enough?

More than likely, no, because there appears to be a new X factor emerging in automotive manufacturing. It’s imperative to know that suppliers are committed to meeting quality and safety standards, achieving continuous improvement, and providing responsive customer service. But more questions need to be asked, and their answers require a bit more due diligence. The supply chain disruptions of the past two years have brought home just how important it is for automakers to know their suppliers.

When evaluating a potential supplier, it’s important to know if it has enough visibility into its supply chain to identify potential risks. Can it mitigate those risks? Does it have sufficient capital to sustain its operations if a supply chain disruption occurs? Even more important, has it shown the ability to be not just a supplier, but a trusted partner to its customers?

A metal casting supplier that checks these boxes in the affirmative is Grede Foundries, Inc., a company with roots dating back to 1920. That’s when its founder, William J. Grede, purchased what was then known as the Liberty Foundry in Wauwatosa, Wisconsin, and renamed it Grede Foundries. But today, as Grede celebrates the 101st anniversary of its founding, the manufacturer of highly-engineered cast and machined iron components has its focus trained squarely on the future.

“We view ourselves as a new company that’s just recently been stood up on its own,” said Tony Lovell, president and head of commercial, in a phone interview. “We’ve got a great balance sheet and we have plans to continue to grow, organically and inorganically.”

Grede began riding a new growth trajectory in late 2019 after exiting its parent company, American Axle & Manufacturing Holdings, Inc., and repositioning itself as an independent provider of engineered iron castings for the automotive, commercial vehicle, and industrial markets. Based in Southfield, Michigan, Grede is now owned by Gamut Capital Management, a New York City-based private equity firm that manages a reported $1.2 billion in middle market assets.

In August, Grede purchased Neenah Enterprises, Inc.’s (NEI) Advanced Cast Products (ACP) business in Meadville, Pennsylvania, along with select portions of NEI’s industrial casting business, and the commercial vehicle business of Neenah Foundry. Grede CEO Cary Wood said in a statement that the acquisition was part of Grede’s strategy to increase its “capacity, flexibility, and innovative engineering resources” for the benefit of its customers. The acquisition will add some 250 ACP employees to Grede’s team while expanding its capabilities and manufacturing footprint.

“We’ve got assets here in the U.S. and capabilities that have a long history,” Lovell told D2P in the interview. “We want to be a mission-critical operator, seamlessly moving and providing highly engineered, highly cast solutions and exceeding the expectations of our customers, our suppliers, employees, communities, and our investors.”

A Broad Mix of Products and Services

Grede manufactures chassis, suspension, and drivetrain components for automotive customers, as well as engine and chassis components for heavy-duty truck engines. The company also produces large axle housings and drivetrain components for makers of agricultural and heavy equipment. About a third of Grede’s business is with automotive, industrial, or commercial vehicle OEMs, Lovell said, with the remaining two-thirds going to Tier-1 and Tier-2 suppliers.

“We’ve always had a very large core focus on the ductile iron and gray iron segment,” Lovell said, adding that although Grede dabbled a bit in forged steel and aluminum in the past, it has since divested that portion of its business. “We are now strictly focused on the iron market. That’s where our expertise is and where we’re going to continue to focus.”

Lovell added that Grede is capable of manufacturing castings ranging from 1 pound to 2,000 pounds. Much of the company’s work for automotive customers involves production of steering knuckles, control arms, brake calipers, brake disc cases, and brake disc carriers. For heavy trucks, it leans more toward manufacturing suspension brackets and carriers. The industrial market, which includes construction, off-highway, agricultural, and railway equipment, has the company producing parts like valve housings, brackets, and manifolds.

“There are many other [part applications], but that’s typically where we find the majority of our volume,” said Susan Bear, director of engineering, program management, and quality, in the interview.

Grede also provides precision machining services, along with in-house finishing and assembly of components. With 30 different molding lines and nine foundries, the company offers a product mix and breadth of services that other companies can’t match, Lovell said.

“If it’s industrial, if it’s CV (commercial vehicle), if it’s automotive, we’ve got facilities that have the know-how to manufacture parts in all those segments,” he said.

Seeing Opportunity in Challenges

That know-how includes manufacturing parts for electric vehicles (EVs), whether they’re for cars or heavy trucks. Bear said Grede is seeing evidence of the industry’s move toward EVs and lighter weight parts, a transition that’s reflected in its business.

A Grede team member pours molten iron into a casting mold. (Photo courtesy of Grede Foundries, Inc.)

A Grede team member pours molten iron into a casting mold. (Photo courtesy of Grede Foundries, Inc.)

“We’re involved with many of the EV customers in working on designs for brackets and unique components that typically aren’t in the internal combustion engine, but that need some type of casting,” she said. “We’re trending in a good direction in terms of capturing some of that market.”

The COVID-19 pandemic and the semiconductor chip shortage have wreaked havoc among automakers and their suppliers over the last year and a half, and Grede hasn’t been spared the effects. The chip shortage is hitting the automotive segment of Grede’s business the hardest, according to Lovell.

“That’s been a big challenge for us. The commercial vehicle segment is starting to get hit a little bit more now—we’ve started to see bits of slowdowns there—but industrial seems a bit insulated so far,” he said. “All of our customers—Tier Ones and direct OEMs—are working diligently to try to fix that supply chain issue. But it has definitely been a challenge across the board for us and for others.”

Despite the challenges of COVID and the chip shortage, Lovell sees somewhat of a silver lining in how Grede and its customers have dealt with the obstacles. Greater visibility has helped to identify supply chain risks that may not have been on the radar earlier.

“I think the supply chain and the customer relationships have gotten better. There’s a lot more collaboration, so I think that we’re all growing through these pains,” he said.

Engineering Excellence

As a manufacturer of highly engineered cast components, Grede prides itself on its engineering talent. “Welcome to excellence in American engineering,” the company’s homepage beckons.

“At Grede, we specialize in safety-critical components for use in automobiles, industrial machinery, and commercial trucks. From concept to completion, we partner closely with our customers to provide highly engineered iron castings,” Grede states on its website. “We’ve earned the trust of our suppliers and our customers through our steadfast commitments to quality, operational excellence, and technology leadership.”

Grede has approximately 100 engineers working to solve its customers’ product development and part production challenges. That includes a foundry engineering team at each of its facilities, and a product engineering team of about 10 people at its Southfield, Michigan corporate headquarters.

Much of the product engineering at the corporate office is focused on pre-launch work—CAD, finite element analysis (FEA), and testing—that Grede performs when designing a customer’s component from scratch. Once a part is in production, the team also leads any engineering efforts to pull unnecessary costs out of its manufacturing, Bear said.

The company recently strengthened its pre-launch capabilities by integrating a new process with numerous checkpoints to ensure part designs are ready for production. It’s called the Grede Project System (GPS), and Bear said it represents a cultural shift within its engineering group.

“It’s a very in-depth system, from quoting to SOP (start of production), where we have very specific deliverables, approvals, and checks that need to be done to ensure that we’re doing all the engineering and pre-validation of PPAP (production part approval process) on the product before the customer gets it into production,” Bear said. “We integrated it last year after we spun from American Axle, and it has really caught on, within the group, that the culture—and how we follow the launch process—is changing.”

Roadshow Days

Grede started a “Customer Roadshow” initiative early this year to share relevant engineering know-how with customers through its Casting Technical Excellence (CTE) program. The program helps customers learn the ins and outs of casting design from Grede’s engineers. It offers eight educational modules, presented over two days, that teach customers about the casting process and how to optimize their part designs for function, quality, and cost-effectiveness.

Underpinning it all is a focus on value analysis/value engineering (VA/VE), a problem solving approach that seeks to maximize value—in this case, part performance and function—while reducing unnecessary costs.

So far this year, Grede has done about a half dozen of the roadshows, and all but one have been virtual due to COVID. “We would love to get it in-house and do it onsite,” Bear said. The modules cover topics from machining to casting materials, to optimizing design, to draft angle, to how to make a lightweight casting.

“One, we’re trying to help them understand where they can save some cost. And two, from an engineering perspective, we’re trying to change the way the industry thinks about casting. In the past, castings have always been the afterthought,” she said.

By that, Bear meant that an OEM would typically design a part, send the design out to casting suppliers, and ask them to quote it. By then, the design was locked in.

“We’re starting to build an engineering relationship upfront, in the early stages, pre-RFQ, where we’re giving input and helping customers design optimally,” she added. “From an engineering standpoint, from a manufacturing standpoint, and from a quality standpoint, we’re setting ourselves and the customer up for success by giving them an optimized design from the start.”

When casting a ductile or gray iron part, it can be very difficult to transition from a thin area of the part to a thick area. Grede’s engineers demonstrate a solution to this problem, showing customers how to make the transition smoothly without compromising the part. Other highlights of the Casting Technical Excellence roadshow include illustrating how to create thin wall sections without creating scrap issues, what specifications could mean in different areas of different products, and how to pull out cost from existing products, Bear said.

Most of the castings produced by Grede, such as brake components, are highly complex parts that pose a variety of production challenges. Many of the large axle carriers, for example, have multiple cores that need to be assembled to pour a part. Other parts require extensive machining.

“When you have products that are nearly 100 percent machined, you really have to be spot-on from an operational standpoint,” Bear said. “There are a lot of difficulties there, and when you get into different materials, it often becomes a bit of a challenge.”

Ensuring Quality for Safety-Critical Parts

Suspension components are also safety-critical parts with challenging material specifications and tight dimensional tolerances. For parts like these, it’s essential to ensure there are no quality defects. To support this ever-important goal, Grede introduced a new system designed to bolster its quality management effectiveness. It’s called the Grede Quality System (GQS) and, according to Bear, it goes beyond the IATF 16949 quality management standard for the automotive industry.

“This is an extensive and very casting-specific system, with 35 different elements of the quality system. We do self-audits, and we do cross-corporate calibrated audits on each plant once a year.” Grede’s goal, she added, is to continue to improve the system so that it ultimately becomes a Best in Class quality management system.