Looks as good as it performs (impressive, we know)

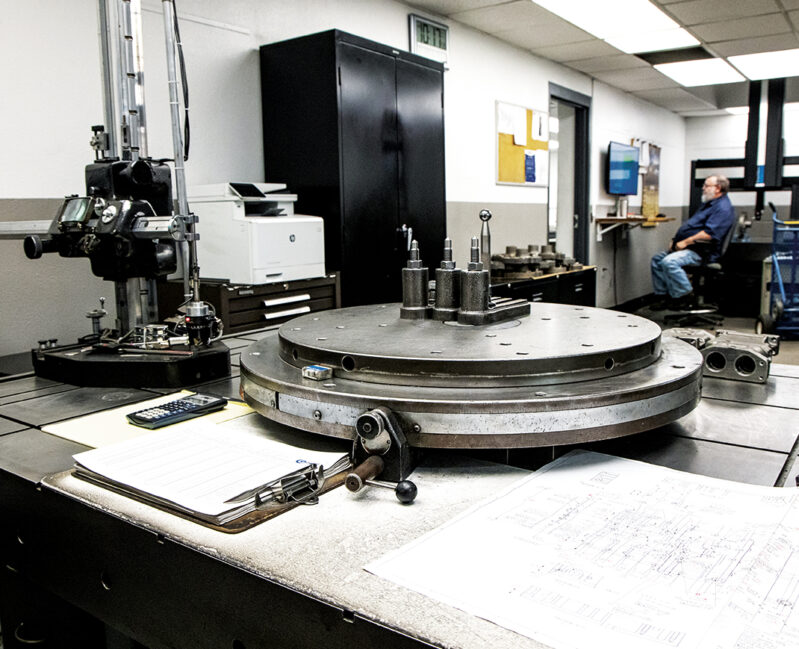

We design, engineer, test, and validate metal forming and casting technologies for our partners. But that’s not all. With robust engineering and project management processes in place, we strive to provide our customers with the best capabilities in both design and manufacturing.

Our customers are experts in fit, form, and function to manufacture their vehicles. However, they might not know the technicalities and requirements of the casting manufacturing process. That’s where Grede’s engineering design team comes in. Everyone’s bottom line improves with efficient casting designs. Our design team offers six services:

Lightweighting Demand

The exact timeline for EV market dominance remains uncertain. However, one thing is clear: the demand for lightweight casting is unequivocal and immediate. Regardless of when the EV market reaches its full maturity, the benefits of reducing weight, including enhanced efficiency and decreased energy consumption, are an essential strategy for all vehicle markets.

Grede has been at the forefront of design and engineering in lightweight castings. With 100 years of expertise, we have pioneered innovations and set benchmarks for the industry, emphasizing our commitment to advancing sustainable and efficient solutions.

Initial Design Concept

Grede can begin the casting design at your proof-of-concept phase. Our product engineers have experience understanding your product needs for fit, form, and function, so first concepts are on target as potential solutions to your needs.

Design Optimization

So, you have a casting design… but can it be made? Is it too heavy? Our expertise in addressing design for optimal casting production while not only meeting fit, form, and function requirements but also aiming to offer weight-saving ideas with improved manufacturability.

Material Optimization

We’ll help you pinpoint the optimal materials that meet the product requirements and deliver the highest efficiency in production while minimizing costs. Alternative or higher-strength materials may allow design modifications and lightweighting without sacrificing performance. We’ll help you take full advantage of material options, determine the grade of iron based on requirements, and select the material best suited for the application.

Advanced Manufacturing Techniques

Our sand core 3D printers can produce complex geometries that are optimized for lightweighting without the constraints of traditional core-making processes. Grede’s 3D prototype printing in plastics allows us to quickly replicate early product designs to enhance product development and support ancillary tooling development, such as end effectors and gating components.

Design for Manufacturing

Collaborate with us to design and develop products by leveraging our product-knowledgeable engineers and extensive expertise in foundry engineering. These products are optimized for functional requirements and manufacturing, resulting in lightweight, cost-effective solutions.